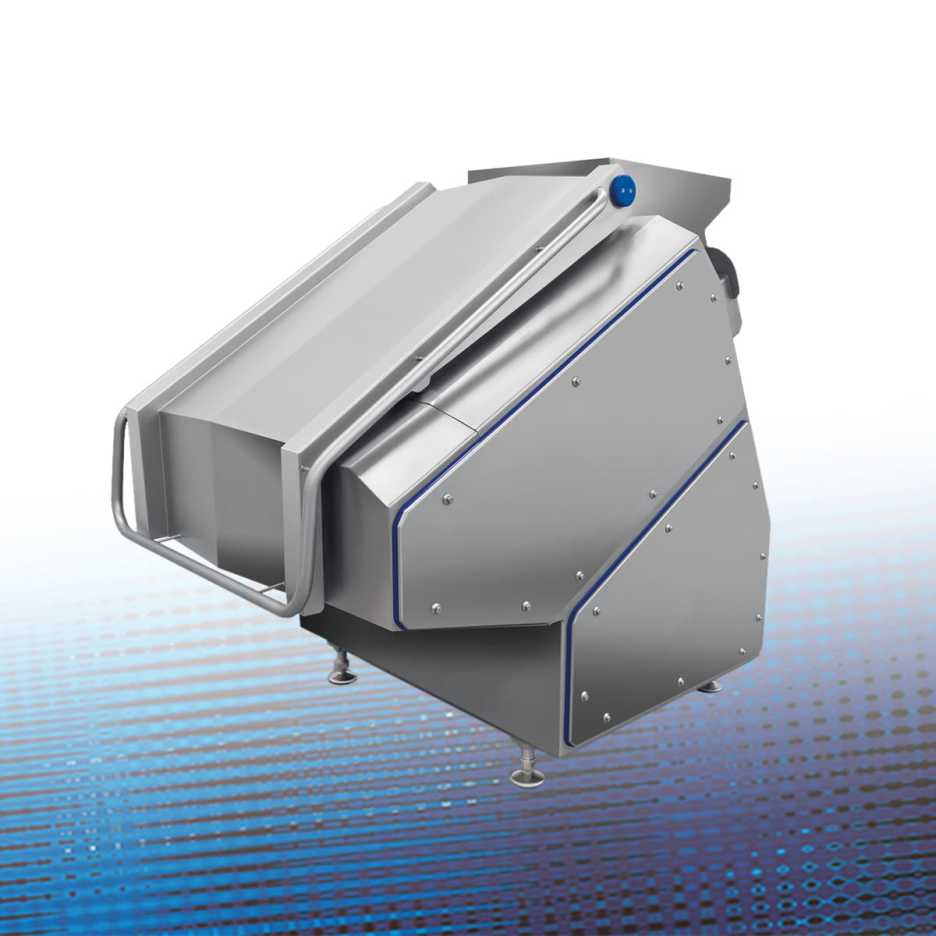

DICECUT®

With maximum accepted block sizes of 420 x 240 x 900 mm (16 ½“ x 9 ½“ x 35“) for the DICECUT® 502 respectively. 630 x 240 x 1100 mm (24 ¾“ x 9 ½“ x 43 ¼“) for the DICECUT® 506 all commonly used EURO- or US-blocks can be used, without the necessity of pre-cutting or deformation of the product as chamber systems work. The dicing machines can be operated by a single person, or also integrated in fully automatic lines, incl. product in-feed and packaging for the cut product.

The DICECUT® GWS are two-dimensionally punch-blade dicers that reduce pre-cut, usually by MAGURIT STARCUTTER or MAGURIT PRECUT frozen block-cutter, into a pieces size that is ideal for the production of wet-pet-food, in cans or cups, pouches or chaps. The advantage is that the cut pieces after sterilisation remain as visible pieces in the final product.